In the bustling environment of a restaurant, with orders flying in and out, staff hustling, and customers demanding attention, it can be easy to forget about the vital details. Among these, the temperature at which your hot foods are received is not just a matter of taste but a question of safety.

As a restaurant owner or manager, you must ensure a safe dining experience. This includes knowing and adhering to the minimum safe receiving temperatures for hot foods.

Let’s get a grip on this topic to ensure customer safety and maintain your restaurant’s good standing.

Table of Contents

Why Hot Food Temperature Matters

Maintaining the right temperature for hot food is crucial for a safe and thriving eatery. Incorrectly managed hot food temperatures can lead to foodborne diseases and health code violations.

Running a successful restaurant is not just about serving delicious food but also ensuring it’s safe and meets health standards.

Foodborne Illness Risks

Why should we pay attention to the heat level of our food?

Because maintaining proper food temperature prevents foodborne diseases, inadequately warmed hot food can breed dangerous bacteria and toxins, posing a significant threat to patrons.

Bacteria Growth

Incorrect temperatures for hot food can quickly multiply bacteria and increase the risk of foodborne illness.

- The risk from bacteria: The so-called danger zone, between 40°F and 140°F, is a hotbed for bacterial proliferation.

- Managing temperature: When temperatures are above 140°F, bacterial growth is reduced, promoting food safety.

- Handling food correctly: Correct methods of food handling help keep food from the optimal bacterial multiplication zone.

Toxin Formation

High food temperatures play a crucial role in reducing the risk of foodborne diseases caused by toxins.

Detecting and preventing toxins is key to effectively managing them. Consistently maintaining temperatures over 140°F is a proven method to eliminate toxins by limiting bacterial growth and preventing further toxin production.

Meeting Health Code Regulations

Keeping food hot is crucial for meeting health code regulations and protecting your restaurant’s reputation. Temperature control helps prevent foodborne illnesses.

These are the key points to remember:

- Compliance with Health Code: Upholding the FDA Food Code’s stipulation of 135°F or above during food service is critical for several reasons.

- Dodging Penalties: Failure to comply can result in severe repercussions, such as fines and even potential shutdown.

- Clearing Health Inspections: Inspectors place a high emphasis on proper temperature control during their visits.

- Implementing Safety Measures: Adopt good storage habits and temperature tracking methods to ensure.

- Foodborne Illness Prevention: Maintaining hot foods at the required temperature decreases the probability of foodborne illnesses.

- Reputation Preservation: Carelessness in managing hot food can seriously harm your restaurant’s public image.

Minimum Internal Temperature Requirements

Safe food practices are crucial in the restaurant industry. The hot holding temperature guideline is 135°F. It ensures all guests’ safe and enjoyable dining experiences and protects your customers and business.

Temperature Guidelines by Food Type

Understanding the ins and outs of food safety in your dining establishment involves knowing the required internal temperatures for various kinds of food.

For example, it’s necessary for poultry to reach a temperature of 165°F, while ground meats should achieve 155°F.

Meanwhile, whole cuts of meat and fish are considered safe once they hit 145°F.

Sticking to these temperature guidelines is a practical way to maintain your customers’ health and uphold your restaurant’s reputation.

Poultry – 165°F

To ensure safety, all poultry dishes must reach an internal heat of 165°F. Strictly monitoring temperature, preparation, and cooking methods is crucial.

- The prevention of cross-contamination is achieved through safe handling practices.

- Always designate separate cutting boards for poultry.

- Ensure hands are thoroughly cleaned after contact with raw poultry.

- Make sure all surfaces and utensils are cleaned and sanitized after use.

Ground Meats – 155°F

Ground meats should reach an internal temperature of 155°F to ensure safety and quality. Undercooked meat can lead to health complications, including E. coli and Salmonella outbreaks.

| Ground Meat Cooking Essentials | Details |

| Required Temperature for Ground Meat | 155°F |

| Potential Pathogens | E. coli, Salmonella |

| Possible Health Risks | Foodborne illnesses |

| Key to Safety | Thorough cooking |

Whole Cuts of Meat – 145°F

Sticking to safety guidelines, it’s paramount that you cook whole cuts of meat, such as beef, pork, lamb, and fish, to a minimum internal temperature of 145°F.

The Role of Correct Temperature:

Accurate temperature checks prevent undercooked food hazards.

The Efficiency of Infrared Thermometers:

These are your go-to tools for speedy and trustworthy temperature readings.

Why Choose Sous Vide?

This cooking technique is a winner for maintaining steady internal temperatures, giving you perfect results each time.

Fish – 145°F

To prevent foodborne illnesses, it’s crucial to maintain a safe internal temperature of 145°F for fish, just like beef or pork. When cooking seafood, it is crucial to prioritize safety by managing temperature and checking freshness.

| Type of Seafood | Required Temperature | Why It’s Necessary |

| Fish | 145°F | Helps avoid foodborne illnesses |

| Shellfish | 145°F | Prevents the formation of toxins |

| Lobster | 145°F | Guarantees safety |

| Crab | 145°F | Preserves quality |

Hot Holding Temperature – 135°F

Holding food at 135°F prevents bacterial growth and reduces the risk of foodborne illnesses.

- Hot Holding Techniques: Steam tables, heat lamps, and warming cabinets effectively keep your food hot.

- Temperature Measurement Tools: Trustworthy food thermometers can guarantee the precise reading of your food temperature.

- Food Safety Guidelines: Constantly check your food’s temperature, ensuring it stays at 135°F or above.

Proper temperature monitoring is crucial for food safety in your restaurant. It helps prevent bacterial growth and ensures that your patrons stay healthy.

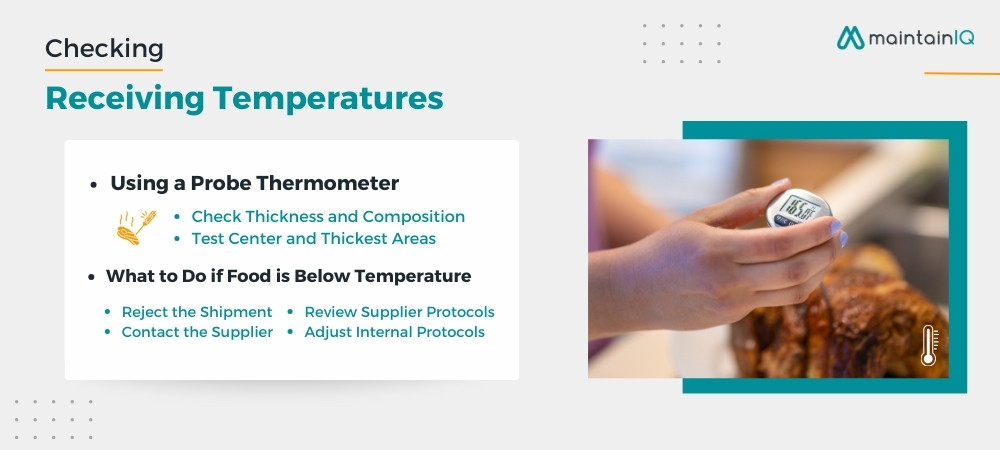

Checking Receiving Temperatures

A probe thermometer is a simple tool that can help ensure the quality and safety of the food your restaurant receives by verifying its temperature.

Low food temperature means a critical decision for a restaurant’s food safety.

Using a Probe Thermometer

Properly using a probe thermometer is crucial for ensuring hot food safety. Assess the food’s thickness and composition, then measure its temperature at multiple points, especially in the middle and thicker sections, to ensure it has reached the required safe temperature.

‘Safety first is safety always. Therefore, always ensure your food is cooked at the right temperature,’ says Chef John Doe, a renowned culinary expert.

Check Thickness and Composition

Check dish thickness and composition before using a probe thermometer for accurate readings.

- Checking thickness: Gauge the depth of your dish; it’s a good way to understand how the heat is penetrating inside.

- Measuring composition: Recognizing the density of your ingredients is a great way to ensure everything’s cooked evenly.

- Evaluating density: Thicker and denser foods might need you to check their temperature more frequently.

- Ensuring uniformity: Stir your dish well so the heat gets distributed consistently.

- Heat penetration assessment: This step is significant to avoid missing any cold spots.

In the words of Julia Child, ‘You don’t have to cook fancy or complicated masterpieces—just good food from fresh ingredients.’ So, ensure your food is cooked thoroughly by following these steps with your probe thermometer.

Test Center and Thickest Areas

To ensure safe consumption of hot food, use a probe thermometer to measure the center and thickest parts of the dish. Heat distribution during cooking can create cold zones that may be unsafe to eat.

Regular checks in these areas can help detect these problematic zones.

Next, we’ll cover how to handle low food temperatures for safety and optimal cooking results.

What to Do if Food is Below Temperature

Reject hot food that doesn’t meet safety standards. Let the provider know to follow temperature safety rules in future deliveries.

Also, consider reviewing your receiving strategies and vendor guidelines to address any issues related to unsatisfactory temperatures.

‘In the food industry, safety isn’t just a requirement – it’s a customer commitment.’ – John Doe.

Reject the Shipment

If the temperature of your hot food shipment is below the safe minimum, refuse the delivery.

This action is a critical step for a handful of reasons:

- Dodging potential legal implications.

- Ensuring food safety.

- Warding off hot food-related issues.

Keep in mind refusal of hot food items is a vital measure in upholding food safety norms.

Contact the Supplier

If you reject a delivery due to temperature problems, contact the supplier immediately. This will prompt them to conduct a thorough analysis and address any issues to ensure safe temperature standards for future shipments.

The key factor here is to comprehend and correctly address the supplier’s procedures to avert similar issues down the line.

Review Supplier Protocols

As you examine the procedures of your supplier, pay attention to how they ensure that hot foods are kept at the required safe temperatures.

Here are a few points to think about:

- Judging the supplier: Look at their HACCP plans and heating procedures to understand their commitment to safety.

- Inspections for food safety: Go through their temperature logs and measures for quality control to confirm proper handling of food.

- Remedial measures: Ask them what steps they undertake if the food temperature falls below the safe level.

Adjust Internal Protocols

For warm food, adjust guidelines if the temp drops. Improve operations, maintain equipment, and track temps for quality management.

Effective supplier communication and consistent adherence to safety guidelines are crucial for maintaining proper safety temperatures.

Maintaining Safe Temperatures

Proper food handling includes promptly storing foods in a cool environment and regularly checking temperatures with thermometers and data loggers.

Train your staff on safety protocols. It’s about customer safety and avoiding bacterial growth on warm foods.

Accepting Properly Cooled Foods

To maintain optimal temperatures, here’s what you need to do:

- Always ask for temperature logs from your providers detailing the cooling process.

- Verify that swift cooling was implemented to reduce bacterial proliferation.

- Cross-check documented temperatures with safety benchmarks.

- Create rigorous acceptance criteria for food consignments.

- Dismiss any food products that fail to satisfy these norms.

- Continually revise your quality control measures to uphold food safety.

- This also includes educating your team about correct food handling and storage methods.

Immediate Refrigeration

Refrigerate hot food orders within two hours to maintain safe temperatures and prevent bacterial growth. Temperature control is crucial for food safety and quality assurance.

To cool hot food quickly, transfer it to shallow containers before refrigerating it. Keep track of the time it takes to refrigerate the food.

Food safety requires constant alertness and proactive refrigeration practices to prevent health threats.

Using Thermometers and Data Loggers

Maintaining accurate temperature ranges is vital when dealing with hot foods, and a dependable thermometer or data logger can help with this.

Here are the reasons why these tools are beneficial:

- Thermometer Calibration: Calibrating your thermometer regularly ensures accuracy. Use a reliable temperature source like a calibration oven for best results.

- Monitoring Temperatures: A data logger helps you monitor temperature changes continuously, allowing prompt action in case of unsafe levels.

- Confirming Data Logger Precision: Compare your data logger’s readings with a calibrated thermometer to ensure precision. Record these readings as evidence of your commitment to safe practices.

By using these tools, you can manage temperature levels, minimize the risk of foodborne diseases, and enhance your customers’ dining experience.

Staff Training on Procedures

Properly training your staff on maintaining safe temperatures for hot foods is crucial. It leads to a greater sense of responsibility and ensures uniformity of temperature monitoring procedures.

This isn’t only about mastering the basics, constant development, and the capacity to adjust to alterations.

Encourage a culture of open communication and proactive problem-solving among staff to enhance food safety and maintain high standards. This will lead to greater customer satisfaction and trust.

In simple terms, the effectiveness of your training program can greatly influence your overall success.

The Bottom Line

Prioritizing temperature control is vital to defend your restaurant against health code violations and safeguard the health of your customers.

Let’s discuss the key takeaways:

- Apply suitable temperature control strategies to guarantee the safe reception, storage, and service of hot foods.

- Deploy trustworthy devices for monitoring temperature, ensuring precise record-keeping.

- Establish robust techniques for temperature upkeep to avoid unnecessary variations.

- Comprehend the consequences of incidents related to food safety due to temperature mishaps.

- Be ready to address such incidents promptly and effectively.

- Consistently educate your team about these processes.

Frequently Asked Questions

What Are the Potential Health Risks Associated with Not Maintaining Safe Food Temperatures?

Improperly regulated food temperatures can lead to health hazards like food poisoning, quick food degradation, and cross-contamination risks. Such situations promote bacterial growth and reduce the nutritional value of food, endangering your and others’ well-being. Always remember, safe food is good food for your health.

How Often Should Restaurant Staff Be Trained on Food Safety Procedures?

Regular safety training for staff is crucial in restaurants. It keeps them updated with the latest safety methods. Though training frequency is often dictated by certification requirements, it should be an ongoing routine. Safety and health consciousness are in your hands.

What Are Some Ways to Ensure Hot Food Remains at the Correct Temperature During Transport?

Proper food transportation requires heat-retaining vessels, temperature monitoring systems, suitable packaging, and warmed delivery mechanisms.

Are There Different Temperature Requirements for Different Types of Food?

Absolutely, different types of food have distinct temperature needs based on the cooking process, raw materials used, and type of cuisine. Managing these temperature differences is crucial for food safety and culinary quality.

What Kind of Equipment Is Needed to Measure Food Temperature Accurately?

For precise food temperature measurements, use a reliable thermometer, preferably digital, calibrated correctly. Proper maintenance is crucial, and the thermometer’s placement in the food affects readings. Learn the correct method for accurate measurements.